Workstation Monitor, Dual Operator Continuous Monitor

Desco Industries, Inc.

Specifications

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

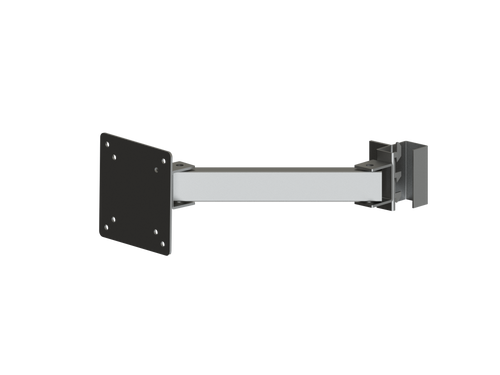

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)

Product Description

Workstation Monitor, Dual Operator Continuous Monitor

Specifications

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)

Product Videos

Custom Field

Specifications

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)

Continuously Monitors Two Operators and Worksurface

FEATURES BENEFITS

Two banana jacks to continuously monitor two operators, carts, or visitors. Mounting bracket and two Remote Jacks included allows mounting main unit at eye level, not using any work surface area.

Wave Distortion Technology provides real-time monitoring. Most models monitor ESD workstation including wrist strap, worksurface, and ground cord. Pays for itself - ensures ESD protected workstation, reducing catastrophic failures and latent defects. Utilizes reliable wave distortion technology tp provide true 100% continuous monitoring. Not pulsed current that’s off over 90% of time. Can use with any brand of single-wire wrist strap and coil cord components. Life-cycle costs of monitor/wrist strap/cord are 66% lower than dual-wire approach. Miniscule electrical current required to generate waveform. No reported case of skin irritation.

Designed for use by 5 foot tall 90 pound to 6 foot 5 inch 250 pound person Individual adjustment for each operator is not necessary.

Provided with calibration to NIST traceable standards. Important for users to maintain NIST calibration at their facility.

Calibration unit available. Simple and quick means to assure accurate performance and conform with ANSI/ESD S20.20 Paragraph 6.2.2.2. Provides lower \calibration life cycle costs.

Note: Continuous Monitors pay for themselves improving quality, productivity, eliminating wrist strap daily testing and test result logging. Per ESD-S1.1 paragraph 6.1.3 Frequency of Functional Testing The wrist strap system should be tested daily to ensure proper electrical value. Daily testing may be omitted if constant monitoring is used.

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if the products that are being produced are of such value that knowledge of a continuous, reliable ground is needed, and then continuous monitoring should be considered or even required.

Work surface limit set to 500 Megohms (5 x 10 8)